This is a little business plan project I wrote/designed in my junior year for a car brand I dreamed up. I used a combination of Automation and Beam.NG to create fully machined and 1:1 realistic engines and 3D-modeled vehicle chassis. Attached below is a trailer I made using the models in Beam.NG.

Below this is a little gallery of the vehicle lineup I created.

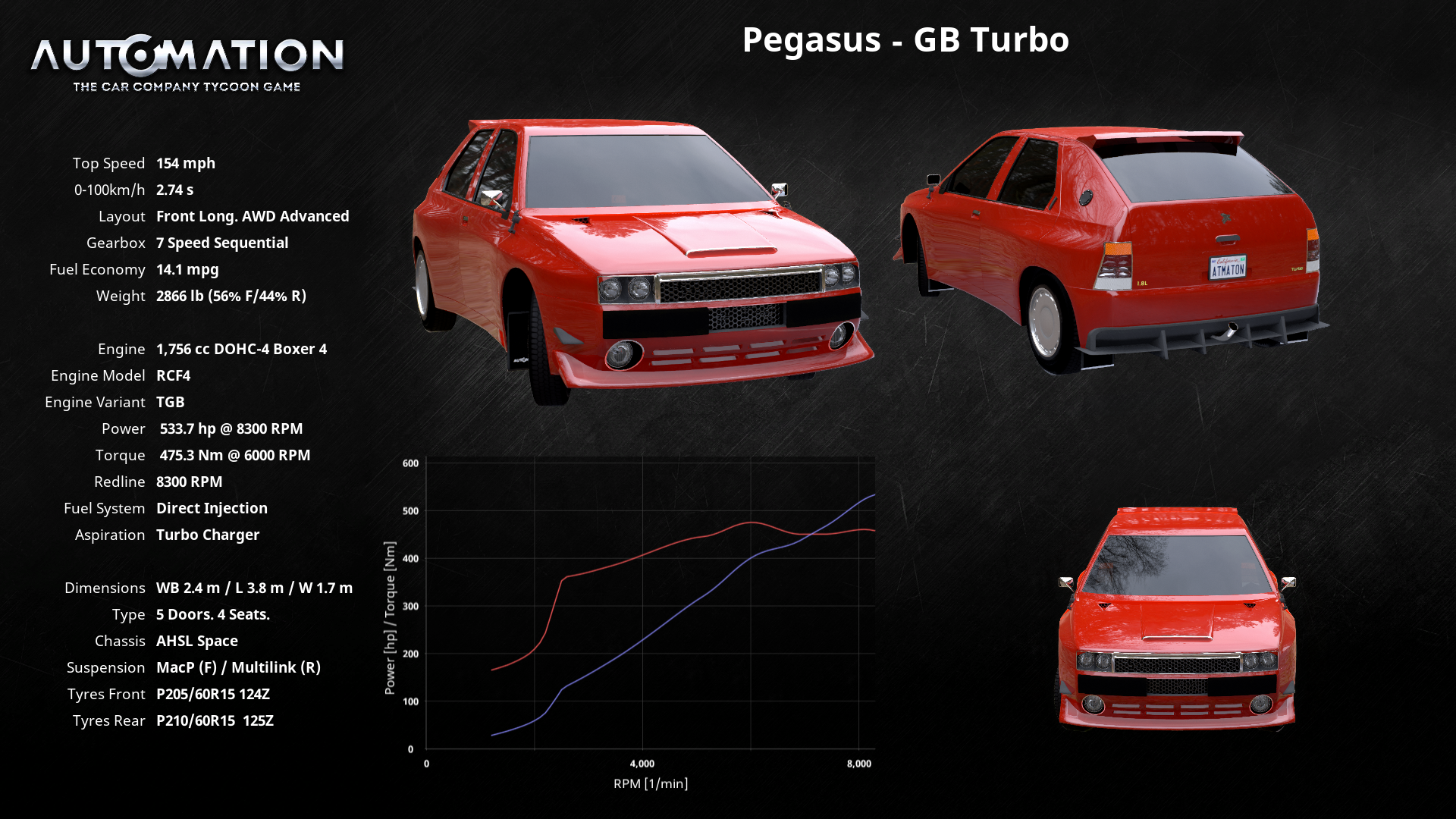

The first two are 4WD Rally racers based on the obvious inspiration, the Lancia Delta HF Integrale. The first one, the GA turbo is intended as a to-spec WRC rally vehicle, with the entire chassis and engine following 2025 specs. The GB turbo is the unrestricted, no-holds-barred version, which is meant to mimic the Group B class of the era in which Lancia competed. The GB doesn’t only feature bolstered internals though, as the exterior styling is also modified for extra downforce and lower weight.

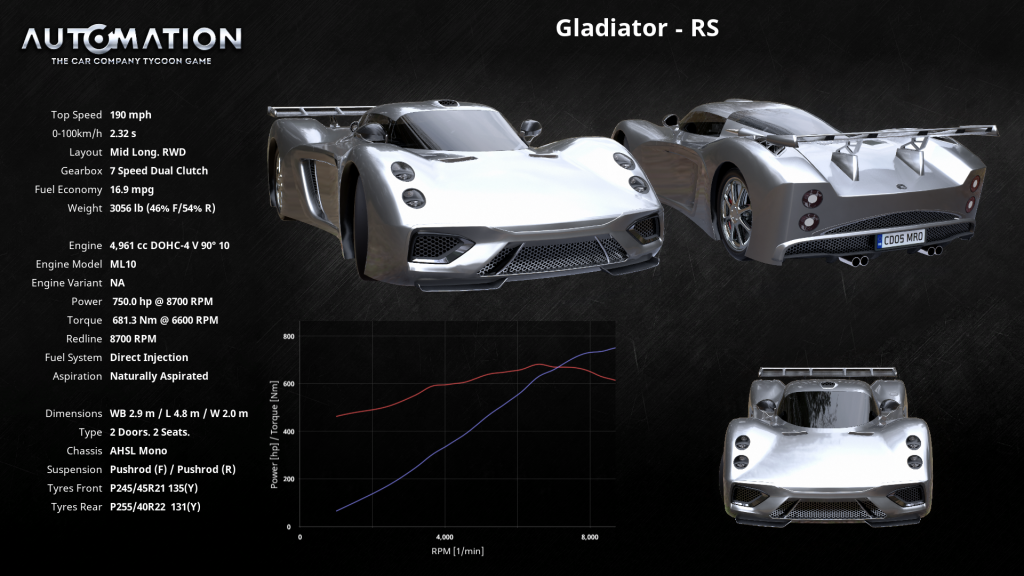

The next three are more of a supercar-hypercar platform geared towards car and racing enthusiasts. They all sport early 2000s Lotus-inspired styling and V10 engines. Why V10? Because nobody makes them, and they’re the best-sounding engine out there. I have a lot less to say about the design behind the base model, although I love the double vertical headlight arrangement. This car feels to me like the lovechild of the Lotus Elise GT1 and the Mercedes-Benz CLK GTR. The first model, the Gladiator RS, is meant to be more consumer-friendly, while the RSC is supposed to be a collector’s item, as it’s just an RS with a full carbon body.

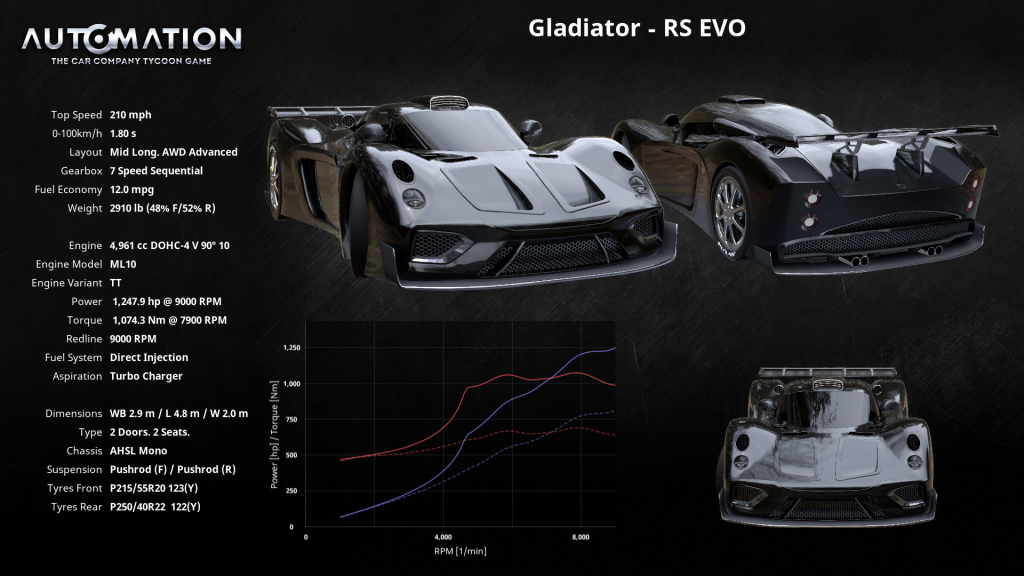

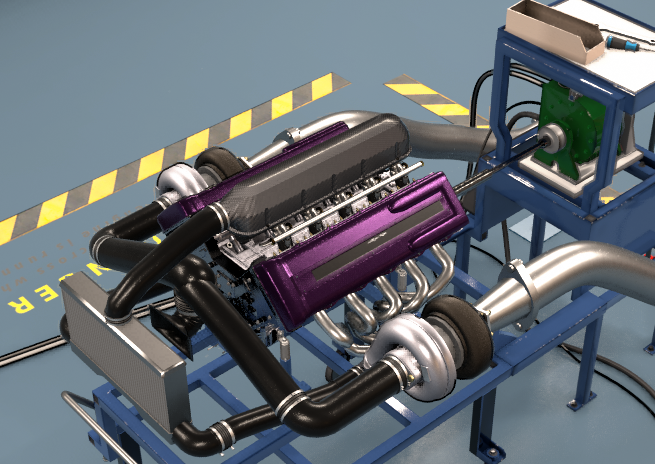

My favorite by far though is definitely the RS EVO. I still get chills just talking about it. Deeper side vents for the rear brakes, huge wing, jacked-up side and hood vents for increased airflow to the mid-mounted engine, huge hood pass-throughs for metric tons of front downforce, and a twin-turbo freak of an engine; but I’ll talk about that in a sec. This car was definitely the hardest to make. I’ve probably spent the better part of 5 hours fine-tuning the turbo timing, weight distribution, and suspension on this thing. Honestly, my biggest breakthrough was switching to an Active AWD drivetrain to counteract the wicked oversteer this thing gets past 100. This thing is a monster and I wish I could port from Beam.NG into Assetto because I’d love to take this thing around the ring.

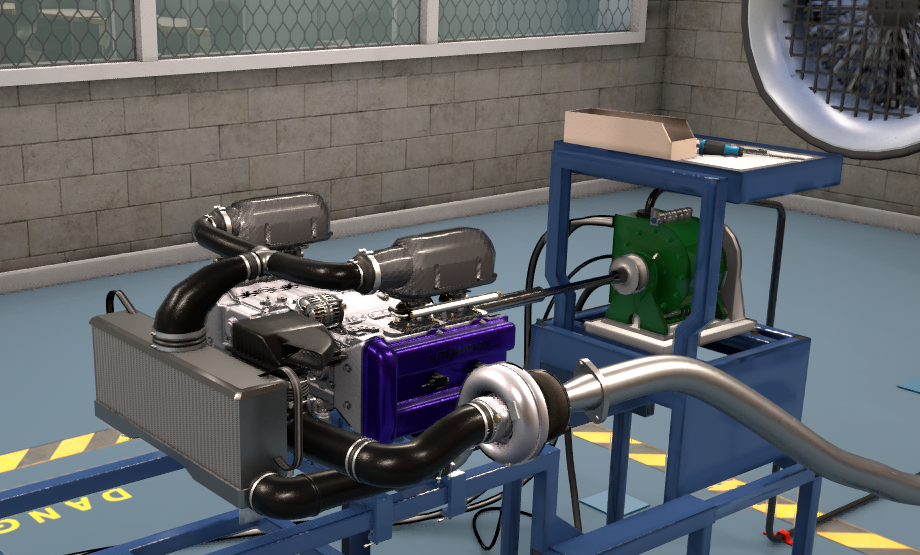

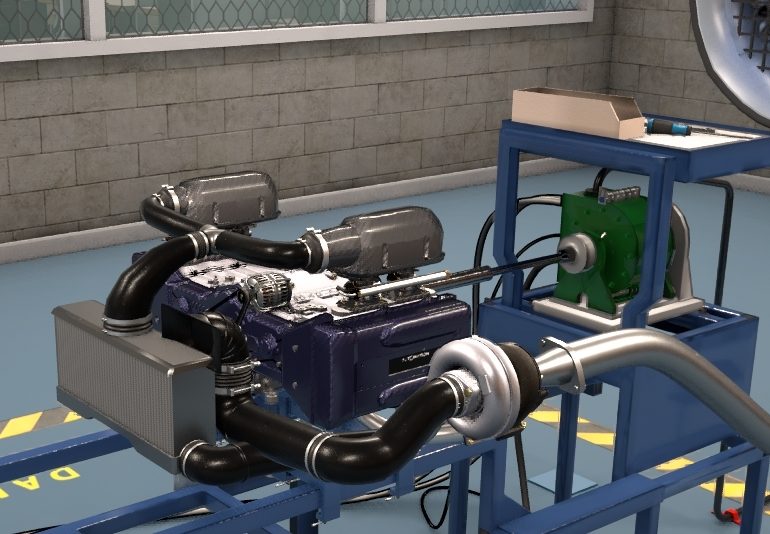

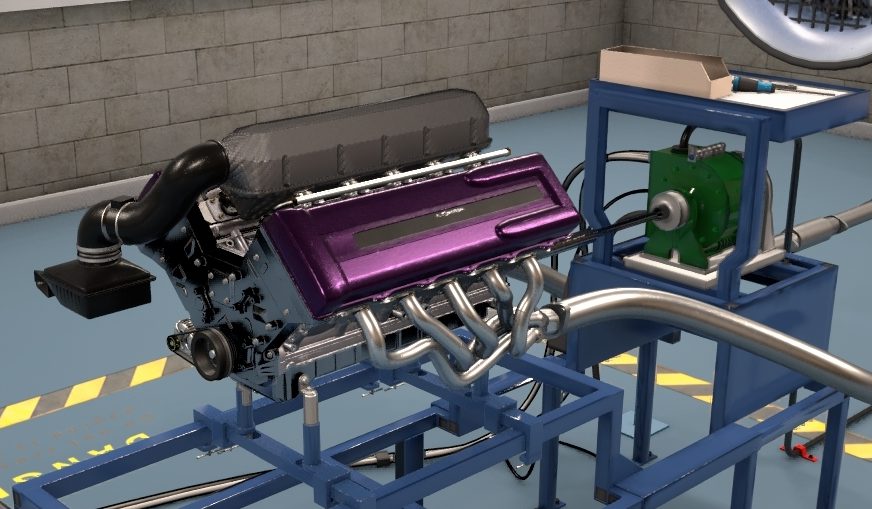

Above are the four engines I designed for the cars featured. The RSC has the same engine as the base RS (anything else and it would probably take flight), so there wasn’t a need for a fifth. In order they are: RCF4-TP, RCF4-TGB, ML10-NA, ML10-TT. RCF4 stands for Rally Chassis Flat 4, as they are flat 4-cylinder engines, TP means Turbo Pegasus, after the model it is intended for, and TGB means Turbo Group B, as it is the unrestricted Group B variant found in the GB. ML10 stands for Main Line 10 Cylinder, as they are the main cars I had been putting effort into developing, and NA and TT are just Naturally Aspirated and Twin Turbo.

The RCF4 platform was a fun little starter project to warm up for the ML engines. They’re made of heavyweight Aluminum-Silicone composite with an 84.0 mm bore and 79.2 mm stroke, and a 16v DOHC valvetrain on an Aluminum head. Internals are fully forged with a 9.0:1 compression on the TGB, and an 11.0:1 compression on the TP to account for the lower pressure internals. Both feature all-cylinder VVT and boost control on a variable geometry single turbo, capped at 10.88 psi for the TP, and 16.68 psi for the TGB. Dimensions are 78.5 mm on the exducer and 57.0 mm on the inducer for the TP, and 77.5 mm by 56.3 mm for the exducer and inducer on the TGB. Both are direct-injected and tuned for 91 octane with an 8300 rpm redline. Beyond that, the only other difference between the two is the track-only exhaust configuration, with high-flow cats present on the TGB, while the TP conforms to EPA regulations. If you know anything about engines, you’ll be able to tell that I used some odd means to down-tune the TP to fit regulations. I have a habit of accidentally making my engines too fast and having to cut down speeds without compromising on things like turbo size and fuel mixture. Both of them also sport a slight bump in heat of the turbo compressor after 7000 rpm, but it’s nothing to be worried about, as it’s to be expected from a single turbo running at full boost. Regardless, the TP and TGB still pull 379.9 and 533.7 horsepower respectively at 8300 rpm, and 369.8/475.3 nm of torque at their peak torque values.

The ML10 was where I felt like my creativity could really pull through, as I spent most of my time on the two of the family. For the ML10, I opted to use a lighter Aluminum-Silicon composite mixture to save on weight for the base model. It has an 82.5 mm bore and 92.8 mm stroke in a 90-degree V configuration, and the Aluminum-Silicone head sports a 40v DOHC valvetrain. Both have forged internals with balancing shafts and quad cam VVT. First looking at the naturally aspirated variant, it runs an 11.5:1 compression ratio with sport cams and semi-stiff springs. It’s capped at 8700 rpm and is tuned for 91 octane on a direct-injected system. All of this comes together to produce exactly 750.0 horsepower at redline and 681.3 nm of torque at 6600 rpm. Unlike the TT variant, the NA is packaged with an EPA-compliant three-way cat system with a muffler.

The ML10-TT is a completely different beast. For the twin-turbo version of the ML10, the forged crank and conrods are replaced with a billet steel crankshaft and hardened titanium conrods to withstand the higher pressures from the turbo’s increased psi. Compression is dropped 10.5:1 to account for turbo compression difference, and the redline is jacked up to a screaming 9000 rpm. However, the TT shines brightest in its namesake, its twin-turbo system. I opted for a variable geometry system with electronically controlled smart boost modulation to even out the horsepower curve. The turbos themselves are massive, with 105.0 mm on the exducer, and 103.4 on the inducer. The ECU is factory-limited to cap the turbos at 9.48 psi of boost, and the entire system is tuned for 93-octane racing fuel. Also, it’s fully open headers minus necessary cats. Because of all of this, it runs at almost double the horsepower, developing 1,247.9 hp at redline, and 1,074.3 nm of torque at 7900 rpm.

I had way too much fun making these, and I’ll probably make more down the line when I find enough free time and interest. Below is a little photoshoot of some of the cars, and below that is the business-focused written assignment associated with this project. It’s just this post but with less engineering jargon and more business jargon. It’s also around 40 pages with somewhere in the ballpark of a 5 figure word count, so it’s definitely not a necessary read.